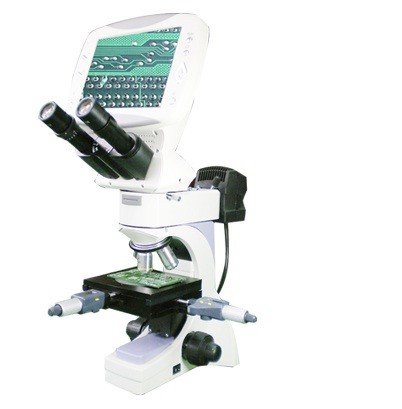

Metallurgical LCD

Showing all 5 resultsSorted by latest

Showing all 5 resultsSorted by latest

A metallurgical LCD microscope is a specialized type of microscope used for the examination of opaque materials such as metals, ceramics, minerals, and other solid materials. It features a high-resolution digital camera and an LCD screen to display the magnified images of the specimen. The microscope uses reflected light to illuminate the specimen from above, allowing for detailed examination of the surface features and internal structures of the material. It is commonly used in material science, metallurgy, manufacturing, and quality control applications. The microscope often comes with different objective lenses and lighting options to accommodate a wide range of materials and applications.

A metallurgical LCD microscope, also known as a metallographic LCD microscope, is a specialized type of microscope designed for the examination and analysis of metal samples. It is commonly used in metallurgy, material science, quality control, and forensic investigations.

Here are some key features and capabilities of a metallurgical LCD microscope:

- Polarized Light and Brightfield Illumination: Metallurgical LCD microscopes typically offer both polarized light and brightfield illumination options. Polarized light can reveal the internal structure and crystallographic properties of metallic samples, while brightfield illumination provides standard lighting for general observation.

- Incident and Transmitted Illumination: These microscopes often have both incident and transmitted illumination sources, allowing for versatile lighting configurations to optimize sample visibility and contrast.

- High Magnification and Resolution: Metallurgical LCD microscopes typically offer high magnification capabilities, allowing for detailed examination of the microstructure of metallic samples. The LCD screen provides a clear and sharp image display.

- Large Stage and Sample Holder: Metallurgical microscopes often feature a large stage and a variety of sample holders or clamps to accommodate different sizes and shapes of metal samples.

- Image Capture and Analysis: Many metallurgical LCD microscopes are equipped with a built-in camera or can be connected to an external camera for capturing images and videos of the samples. These images can be stored, analyzed, and shared for further examination and documentation.

- Advanced Features: Some models may offer additional features such as motorized stage movement, automated focusing, image measurement, and image processing software for more precise and efficient analysis of metal samples.

Metallurgical LCD microscopes are valuable tools for investigating the microstructural characteristics, grain boundaries, phase identification, and defects in metallic materials, which are important for understanding their properties, performance, and quality.