What is a metallurgical microscope?

A simple answer is that a metallurgical microscope is another type of light microscopes and unlike a biological microscope it uses a reflected white light. Obviously the nature of samples is different for such a use, i.e. a metal, semiconductor or plastic rather than a biology slide, cell, living microorganism etc. This also means that a metallurgical microscope needs a high-power light source compared to biological one, For instance 100W halogen (or its equal brightness with LED) rather than a 30W bulb in biological microscopes.

Metallurgical Microscopes Applications

Metallurgical Microscopes are mainly used in metallography, forensic, processing plastics, inspection of metals, semiconductor materials, laser systems, solar cells using both thin films and wafer technology and many other fields of material science. Special use of metallurgical microscopes are to visualize opaque or solid samples, measure thin films, inspection in electroplating, coating, painting, corrosion, corrosion coupon, grain size, surface defects, surface inclusions and features. Samples of ceramics, composites, plastics, polymers, food, metals, particles, porous materials, cosmetics, glass, films, textiles and fibers can be visualized easily with a metallurgical microscope.

Imaging Modes

Most metallurgical microscopes allow imaging in Brightfield, darkfield, polarizing, and DIC Nomarski modes.

Metallurgical Microscope Types

Metallurgical microscopes are divided mainly to 4 categories:

1) Upright Microscopes with reflected light only, in which the light comes from top lamp-house and is used for non-transparent samples

2) Upright Metallurgical Microscopes with reflected and transmitted lights, in which light can come from top and bottom light sources and can be used to examine the transparent and non-transparent samples.

3) Inverted metallurgical Microscopes which includes a lamp house for reflected illumination. Bioimager offers economic external light source to be able to use for tra

4) Boom Stand Metallurgical Microscopes

|

|

|

|

|

Upright Metallurgical Microscope with Reflected light |

Upright Metallurgical Microscope

with Reflected & Transmitted |

Inverted Metallurgical Microscopes | Boom Stand Metallurgical Microscopes |

Key features when you like to buy a metallurgical scope:

Few main features are important when you choose metallurgical microscope

1) Medium, large or extra-large XY stage?

Most of the metallurgical samples are often large, like 6″ or even more. Thus make sure the microscope stage can support that. Most of the metallurgical microscopes come with 4″x4″ or 100x100mm XY stage. If that is not enough, the next version is normally 6×6 in. If you need even larger than a 6″ stage, then choose Bioimager extra large stages which are from 8″, up to 14″. These stages come with anti-vibration table.

|

|

|

|

| 4×4 stage | 6×6 stage | 8-in stage with anti-vibration table | automated XY Stage |

2) Imaging Capabilities

a) BF or DF? By default all metallurgical microscopes come with brightfield (BF) imaging. If you need to have darkfield (DF) imaging, you do need to decide during the purchase time as upgrading such a feature will not only be costly but also will result in loosing the money you spent on BF module and also the obj lenses. Switching between BF and DF is always super easy, just move a lever.

b) DIC Nomarsky or not? DIC Nomarsky imaging needs a polarizer and analyzer. Make sure your microscope does / will come with polarizer, analyzer, slot for DIC insert and also which objective lenses are supported for DIC imaging.

Having DIC Nomarsky is always costly. If your microscope allows having a DIC imaging but your budget does not permit, make sure you can upgrade that by simply purchasing the extra parts without discarding your current obj lenses or setup.

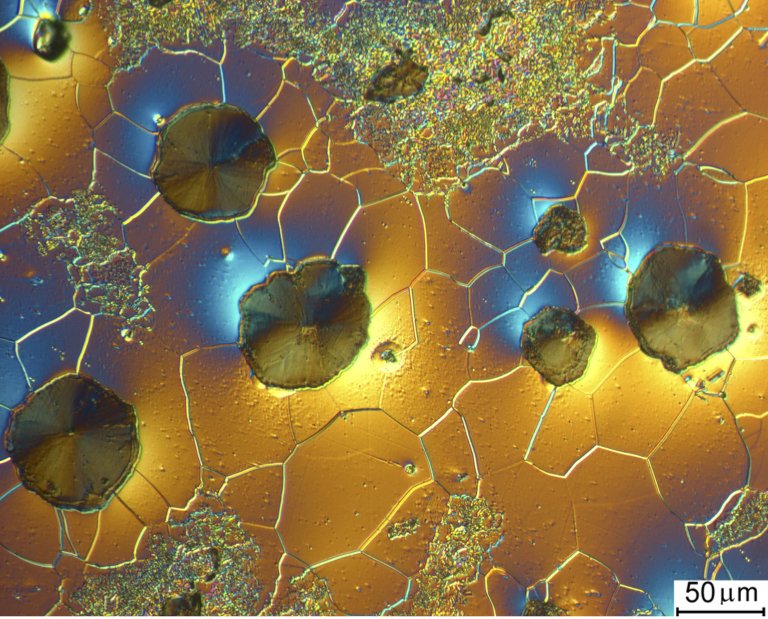

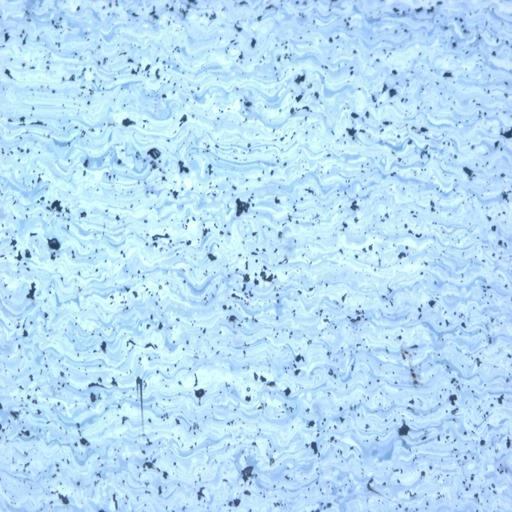

Differential-Interference-contrast image of cast iron with spheroidal graphite, 500X magnification, captured with ProgRes® C14

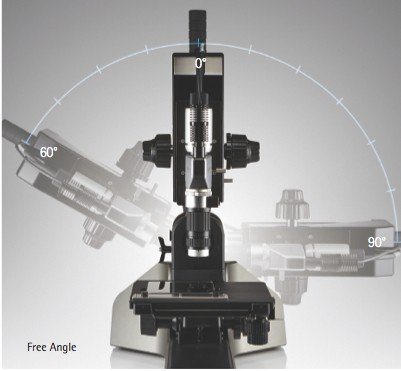

3) 3D Profiler

one of the most interesting and useful feature of the metallurgical microscopes is having a 3D profiler which allows measurement of the height and/or thickness of a sample. This is a great tool for inspection of the materials or scaffold are made in three-dimensional, such as 3D tissue or dental cements. BIOIMAGER has recently added an output format of .stp to the constructed 3D microscopy images then you can easily print out what you observe under microscope.

|

|

| 3D Profile with automated Z focus at 10 nm resolution | 3D Profiler with tilting stand |

illumination Guide for Transmitted & Reflected Light

Transmitted Light

|

Specimen Type |

Imaging Technique |

|

Transparent Specimens -Bacteria, spermatozoa, cells in glass containers, protozoa, mites, fibers, etc. |

Phase Contrast Oblique Illumination |

|

Light Scattering Objects -Diatoms, fibers, hair, fresh water microorganisms, radiolarians, etc |

Darkfield Illumination Phase Contrast |

|

Light Reflecting Specimens -Colloidal suspensions, powders and minerals, liquids |

Phase Contrast Dispersion Staining |

|

Amplitude Specimens -Stained Tissue, naturally colored specimens, hair & fibers, insects and marine algae |

Brightfield Illumination |

|

Fluorescent Specimens -Cells in tissue culture, fluorochrome-stained sections, smears and spreads |

Fluorescence Illumination |

|

Birefringent Specimens -Mineral thin sections, liquid crystals, melted and re-crystallized chemicals, hairs & fibers, bones & feathers |

Polarized Illumination |

Reflected Light

|

Specimen Type |

Imaging Technique |

|

Specular (Reflecting) Surfaces -Thin film, mirrors, polished metallurgical samples, integrated circuits |

Brightfield Illumination Darkfield Illumination |

|

Diffuse (Non-Reflecting) Surfaces -Thick and thin films, rocks & minerals, hair, fiber, bone and insects |

Brightfield Illumination Darkfield Illumination Polarized Illumination |

|

Amplitude Surface Features -Dyed fibers, diffuse metallic specimens, composite materials, polymers |

Brightfield Illumination Darkfield Illumination |

|

Birefringent Specimens -Mineral thin sections, hair & fibers, bones & feathers, single crystals, oriented films |

Polarized Illumination |

|

Fluorescent Specimens -Mounted cells, fluorochrome-stained sections, smears and spreads |

Fluorescence Illumination |

Analysis and measurements

| Field / Sample | Image | Atttributes, Measurement Features, Analysis |

| Ceramics, composites, Plastic |  |

|

| Food |  |

|

| Metals |  |

|

| Particles & Porous materials |  |

|

| Cosmetics |  |

|

| Glass, films, coatings |  |

|

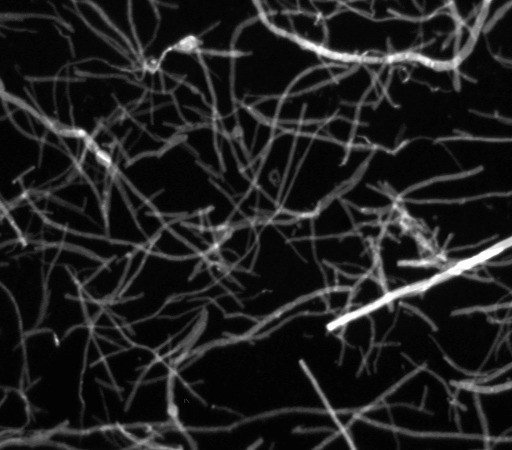

| Textile / Fibers |  |

|

| new materials |  |

|

These features can be analyzed with Image Pro Plus or Image Pro Premier.

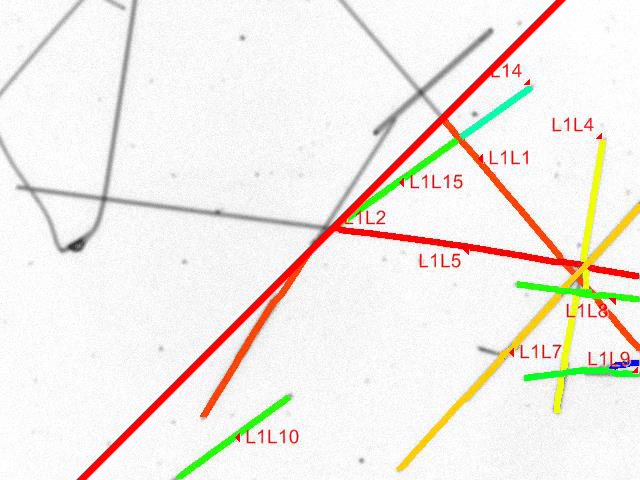

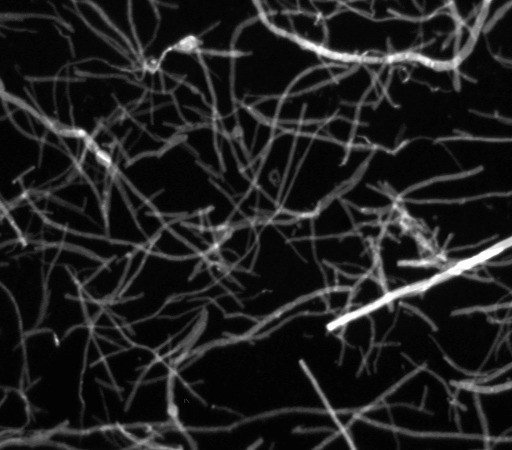

Analysis Example: Fiber Separation Analysis

The application is designed to separate and measure crossing fibers on images. The fibers on the images can be straight or bent. It can be used to measure distribution of thin inclusions or asbestos fibers.

Researchers have been looking for an easier way to measure the lengths and widths of overlapping fibers. Most researchers end up manually measuring fibers – a process that is not only time consuming, but can introduce inconsistencies. Now, with the Image-Pro Premier Fiber Separation App, it is possible to measure and classify the length and thickness of overlapping fibers with one click.

This App is designed for applications where the entire fiber is visible in the image.

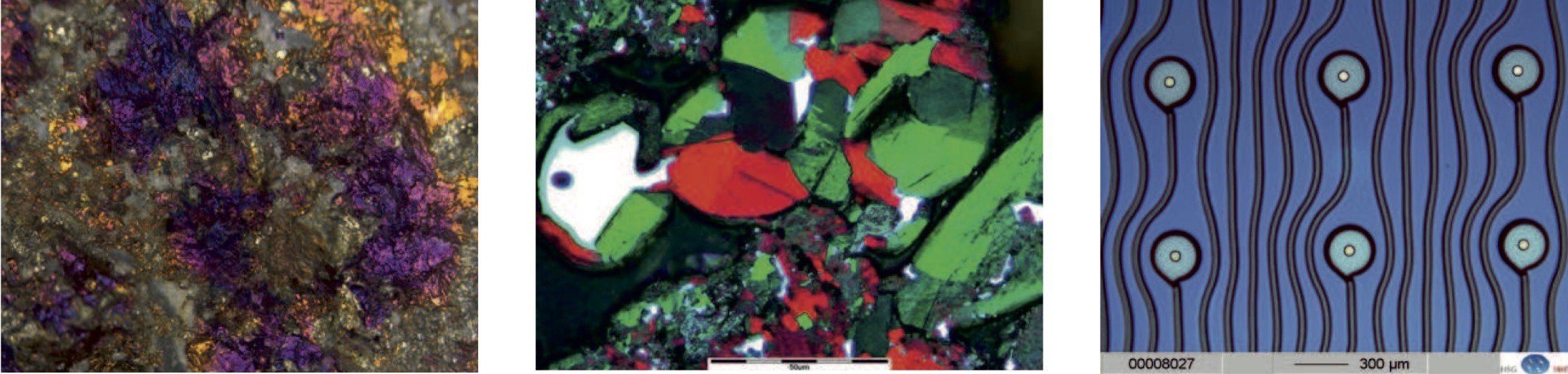

Sample Images / Appplications:

|

||

|

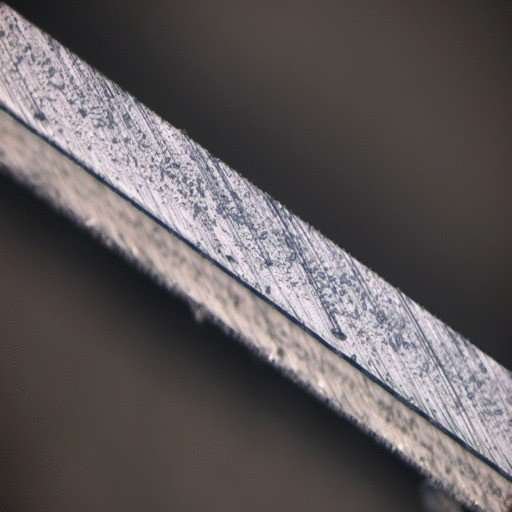

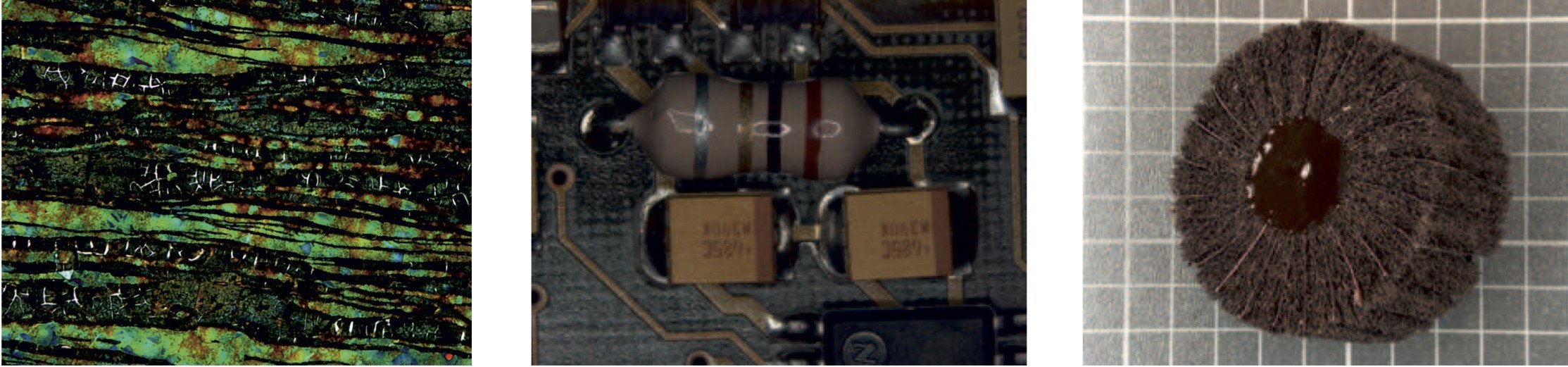

Duplex steel, damaged rotor blade etching: Beraha III, Camera: ProgRes® C5, Courtesy of:Cloeren Technology/Germany |

PC board,Camera:ProgRes® C14,Courtesy of: ProgRes® Application Lab |

Sample:Blower grinding tool,Camera:ProgRes® C14plus,Courtesy of: ProgRes® Application Lab |

|

||

|

Sample:stone on stereo microscopes Camera:ProgRes® C7, Courtesy of: ProgRes® Application Lab |

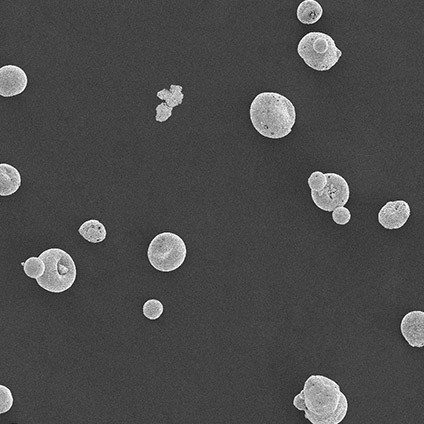

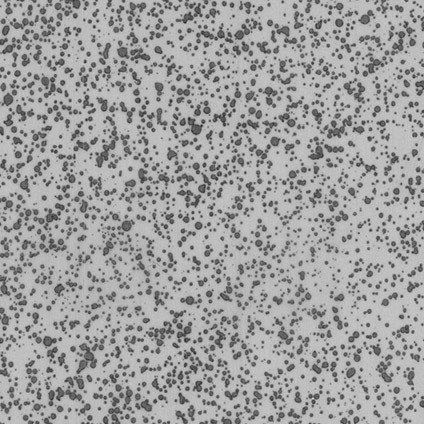

Sample:compound from graphite and powder,Camera:ProgRes® C3, Courtesy of:Hoffmann & Co. Elektrokohle AG, Austria |

Sample:fluid channel fo a press button Camera: ProgRes® 3012, Courtesy of: HSG-IMIT Microtechnology |

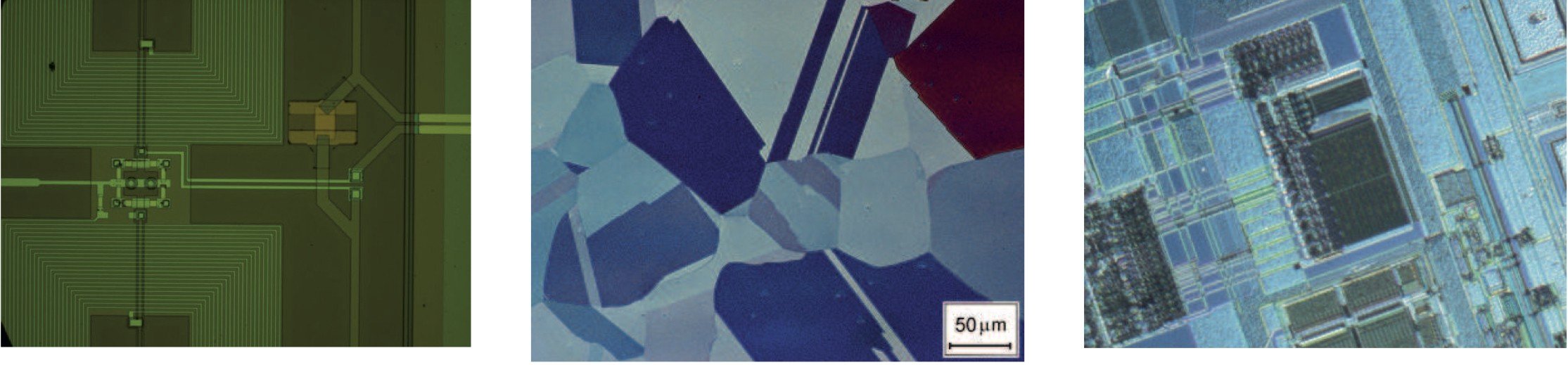

|

||

|

Sample:detail of a SQUID (superconducting quantum interference device), Camera: ProgRes® C3, Courtesy of: MPQ of Radio Astronomy, Bonn, Germany |

Sample:rolled metal sheet, Camera: ProgRes® C14, Courtesy of: MPI for Iron Research GmbH |

Sample:Wafer im DIC Camera:ProgRes® C14plus Courtesy of:Promicron |

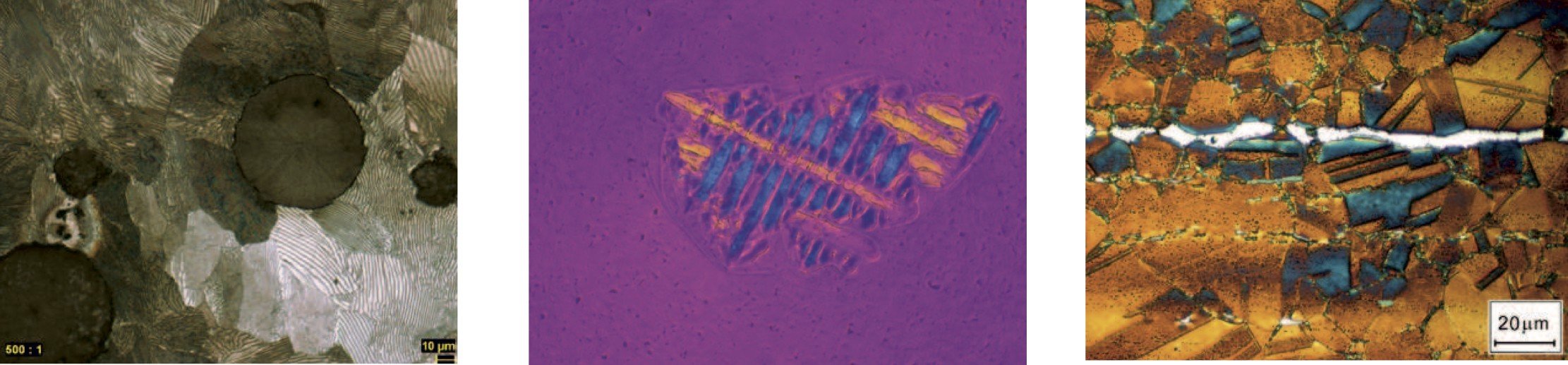

|

||

|

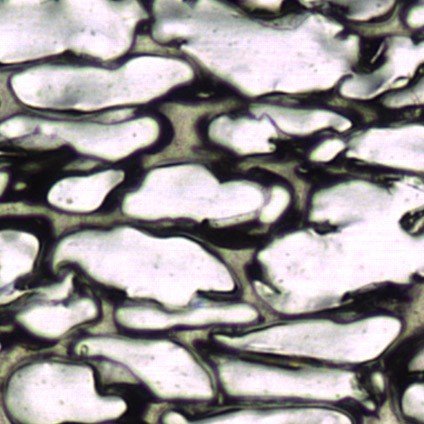

Sample:Cast Iron (spherulitic graphite iron), Camera: ProgRes® C5, Courtesy of: Cloearen Technology, Germany |

Sample:new formation of cristobalite in glass, Camera: ProgRes® C14plus, Courtesy of: Institute of Ceramic, Glass and Building Materials of the Mining Academy |

Sample:TWIP Steel, Camera:ProgRes® C14, Courtesy of: MPI for Iron Research GmbH |