Features

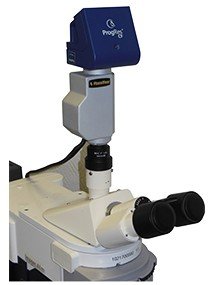

- Compatible with any microscope equipped with video port or Trinocular head

- Compatible with any C-mount Camera

- Z-Scans at any objective lens, no adapter required

- Fast scanning with response time < 5ms

- No sample perturbation: no objective or stage movement causing vibrations

- Sample space kept totally free

- Single USB connection to PC

Applications

- Material Microscopy: 3D surface analysis, surface prameter study, roughness measurment,

- Laser engarving and cutting measurments and profile study

- Fast Z-stack; 3D Microscopy; Rapid Screening; Autofocus; Z Depth Measurement

- Life Sciences: Cell pathology, drug testing, cell dynamics, Zebrafish, real-time biological specimen analysis

- Paint study in polymer engineering

- Art Paint study and inspection

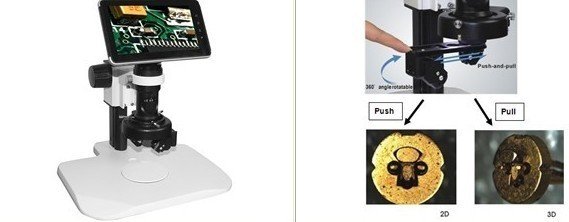

- PCB quality control

OverView

1 – Hardware:

ZeeScan features the most advanced properties for fast and precise z-scanning. Instead of using traditional motorized means such as stepper motors or piezo devices, ZeeScan uses a proprietary PhaseView optical assembly for 3D scanning integrating the latest advances of digital lens technology, leading to accurate and highly repeatable z-steps for 3D acquisition ad analysis.

2 – Software:

ZeeScan is supplied with GUI software GetPhase. An optional API/ SDK is provided for microscopy automated systems with comprehensive 3D acquisition & analysis tools.

Specifications

| ZeeScan | |

| Camera | Compatible with c-mount cameras (format 2/3” or less) Current camera compatibiliy list |

| Microscope interface | video Port – C-mount, recommended 1x c-mount coupler |

| Dimensions & weight ZeeScan Head Control unit |

C-Mount |

| Power supply | 110/220V AC |

| PC interface | USB 2.0 |

Field Of View – Lateral XY resolution – Depth of Field

Field of View (FOV) = (Camera (H/V) resolution * camera pixel (H/V) / (G_Obj * G_adapt)

Depth of Field (DOF) = lambda / NA + pixelsize / (NA? * G_Obj * G_adapt)

G_Obj = objective magnification

G_adapt = c-mount coupler magnification

Lambda = typically 0.633μm

NA = objective numerical aperture

Pixelsize = camera pixel size

Examples with typical objective magnification – camera 1Megapixel – microscope coupler 0.537x

Z Height Measurement*

Z Range = 23mm / (G_Obj * G_adapt)2

Z Resolution = Z Range / 2000

| Objective Mag : NA |

Z Range (μm) | Z Resolution (μm) |

| 5X / 0.10 | 3190 | 1.59 |

| 10X / 0.25 | 797 | 0.4 |

| 20X / 0.45 | 200 | 0.1 |

| 50X / 0.8 | 32 | 0.016 |

| 100X / 0.9 | 8 | 0.004 |

Examples with typical objective magnification – microscope coupler 0.537x

*Intrinsic performance without using image processing algorithms

3D Roughness Measurement*

Z Range = Objective DOF

Z Resolution = Z Range / 100

| Objective Mag : NA |

Max slope (degree) | Z Range (μm) | Z Resolution (μm) |

| 5X / 0.10 | 5.8 | 74 | 0.74 |

| 10X / 0.25 | 14.3 | 12 | 0.12 |

| 20X / 0.45 | 25.8 | 4 | 0.04 |

| 50X / 0.8 | 45.8 | 1 | 0.01 |

| 100X / 0.9 | 51.6 | 1 | 0.01 |

Examples with typical objective magnification

*Using GetPhase image processing algorithm – See software specifications

3D Shape Measurement*

Z Range = 23mm / (G_obj * 0.537)2

Z Resolution = DOF / 4

| Objective Mag : NA |

Z Range (μm) | Z Resolution (μm) |

| 5X / 0.10 | 3190 | 18.5 |

| 10X / 0.25 | 797 | 3 |

| 20X / 0.45 | 200 | 1 |

| 50X / 0.8 | 32 | 0.25 |

| 100X / 0.9 | 8 | 0.25 |

Examples with typical objective magnification – microscope coupler 0.5x

*Using GetPhase image processing algorithm – See software specifications

Z Calibration , Certification & System Calibration

Calibration for the Z axis is performed in Phaseview factory before shipment, using step height certified calibration standard. Checking Z calibration can be easily achieved using step height calibration standard such as Rubert satndard item number 513C (optional)

A system calibration software (see software specifications) is provided for XY calibration according to objective magnification and calculation of corrected XY shift parameters to be applied along the Z axis (Z-stack). The calibration data are then stored in an internal memory of the acquisition system. Typical accessories required for the calibration (optional).

5. Software

Overview

ZeeScan is supplied with the Graphics User Interface « GetPhase « and a System Calibration software. An optional API / SDK is provided for integration purpose. All software are XP, Vista, 7, 8 (32 / 64 bit) compatible, and Graphics Processor Units (GPU) compatible.

GetPhase GUI (included)

Main features:

2D / 3D acquisition modes: 2D, Z-stack, 3D roughness, 3D Shape

Multiple display modes : 3D, Phase, DIC, Darkfield, Image fusion (Extended Depth of Field)

2D / 3D analysis tools : profiles, step height, roughness, etc.

Report & Export Data

GetPhase includes 3 different methods for Z axis and 3D acquisition:

Z Height measurement / Z-Stacking: relies on the unique Z-scanning capability of the PhaseView optical assembly providing accurate and repeatable Z steps.

3D Roughness Measurement: relies on proprietary wavefront technique, for measuring surface topography in reflection. The algorithm processes a set of 2 or more images acquired within objective depth of field. This method is particularly useful for measuring small surface variations, when sample features are all in-focus, within depth of fiel of the selected objective. The 3D reconstruction is determined by the maximum slope constraint; samples with steep slopes require high objective magnification as related to objective numerical aperture (NA).

3D Shape Measurement: relies on detecting local contrast on Z image series for measuring depth map of an object. The algorithm processes Z-stack images acquired beyond the objective depth of field. This method is well adapted to samples having surface variations beyond objective depth of field. 3D reconstruction is performed when samples exhibit some contrast along the Z image planes.

System_Calibration software (Included)

Main features:

XY calibration for each objective magnification

Z-stack alignment parameters calculation

Calibration data are stored in acquisition system memory

API / SDK (Optional)

Routines for Z-stack acquisition and for controls z-scanning parameters

Functions for 3D reconstruction, image fusion (EDF) , multiple views and 3D surface analysis

Reviews

There are no reviews yet.